Optical particle characterization

Particles, be it solid particles, drops, or bubbles, frequently occur in industrial processes as well as in natural environments. The varieties range from drops in sprays at fuel or lacquer nebulization through suspension drops at the spray drying of food products, soot particles of cars and in exhaust gases of power plants, solid particles for detergents and in dusts, to cavitation bubbles or bubbles in chemical reactors.

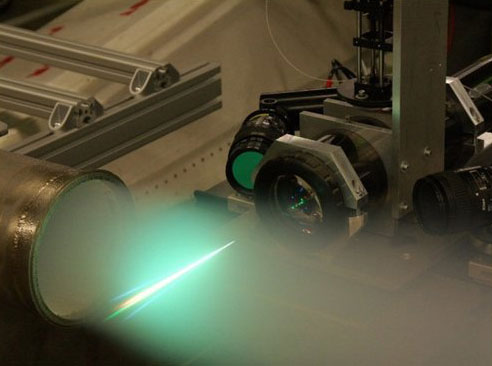

The necessity of characterizing particles becomes clear, when you look at the broad variety of particles and their usages. Therefore, a variety of measurement systems exist to characterize particles. The Institute of General Electrical Engineering at the University of Rostock explores the development and application of optical measurement techniques, which always play a role when a process should be observed or investigated in-situ and contactless. Especially with spray diagnostics this is almost always necessary. Furthermore, many applications require the determination of the particles’ velocity. A direct assignment of velocity to particular particles is inevitable, whenever concentrations or current densities should be determined, for example number, volume, or mass concentration of the dispersion phase. These techniques, which assign qualities like velocity and diameter to each particle, are called counting techniques and are the focus of research and development at the University of Rostock.

Optical in-situ particle measurement techniques

The phase Doppler (PD) measurement technique is applied for the characterization of two-phase flows, e.g. sprays. It is able to determine, contactless, the size (1µm – 500µm) and velocities (up to 200 m/s) of homogeneous spherical particles, e.g. drops, bubbles, etc. Subsequently, number and volume concentrations as well as flows can be deduced from these size and velocity distributions.

Due to its complexity and the high adjustment effort, the PD technique is almost exclusively used in research. The aim of the project is, among others, to develop the PD technique into a reliable process measuring technology. Furthermore, extensions of the phase-Doppler Technique for the characterization of solid particles or, respectively, for the differentiation of particle classes are investigated.

The commercially available PD technique is limited to the size determination of homogeneous spherical particles and requires separate sending and receiving optics in forward or sideward scattering. To reduce the effort in adjustment and equipment, a characterization of the backscattering is attractive, which can be realized by the time-shift technique. In addition, the time-shift technique offers perspectives for the optical characterization of inhomogeneous and non-spherical particles.

Laser-Doppler/Phase-Doppler measurement technique

The Laser Doppler measurement technique is an – also commercially – established procedure to measure the velocity of small particles or surfaces. When crossing two laser beams, an interference pattern with equidistant interference bands is forming in the overlapping area. When a particle or optical inhomogeneity moves through this overlapping area, it scatters the local intensity and the frequency of the detected signal is proportional to the velocity of the particle.

Furthermore, the phase of the signal contains information on the scattering process at the particle and is, under the assumption of homogeneous spherical particles, directly proportional to the particle diameter. Thus, when using two or more spatially separated receivers, the diameters of the individual particles can be determined, in addition to the velocities, within an accuracy of about 1 µm. With this so-called phase-Doppler measurement technique, which by now is indispensable in spray diagnostics, it becomes possible to characterize online hundreds of thousands of homogeneous spherical particles per second in regard to their size and velocity.

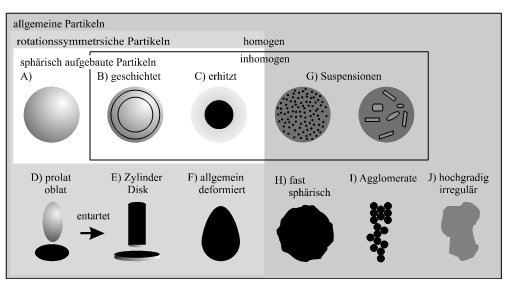

However, the assumption of homogeneous spherical particles limits the application of the phase-Doppler technique to specific measuring tasks like sprays. Especially many solid particles or miniscule biological particles like spores or plankton have rough surfaces or highly non-spherical qualities. Furthermore, suspension drops, like for example in milk or coffee sprays, are not homogeneous in spray drying. Due to the fact that no contactless counting procedure exists for this problem, processes with such particles can hardly be characterized so far. An exception are direct camera images, but they require at least two optical entrances for lighting and observation and they can only be employed off-line or for slow processes due to their limited image repeat rate and the mostly extensive image processing.

The development of optical measuring techniques first of all requires a fundamental understanding of light scattering at small particles, which is, among others, a research subject at the Institute of General Electrical Engineering. Even the light scattering at homogeneous spherical particles, the Lorenz-Mie theory, leads to complex light scatter features (see picture below), especially when using inhomogeneous laser beam profiles or pulse scattering of, for example, femtosecond lasers. With the scattering at non-spherical and inhomogeneous particles, even the description of the particles depends on statistic models and a calculation is rarely possible.

Time-Shift technique

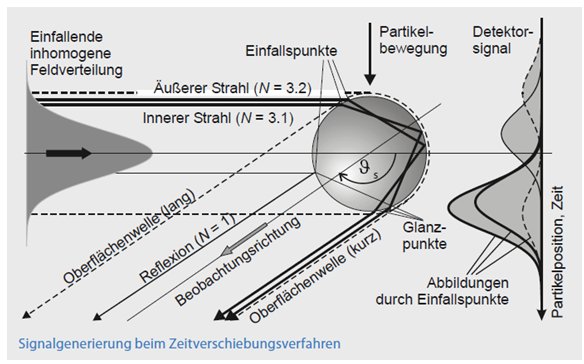

The Time-Shift technique, which was developed at the Institute of General Electrical Engineering at the University of Rostock, allows researchers to bypass the limits of the phase-Doppler technique. The procedure is based on the scattering of an inhomogeneous light beam, for example a laser beam, at small particles. Since for one lighting direction and one receiver position only selected beams contribute to the detected signal, the so-called points of incidence of these selected beams scan the spatial intensity distribution (see picture above).

When the particle moves through the incident laser beam, each beam path generates an own time-delayed signal. When the particle velocity is measured simultaneously, the local mismatch of the points of incidence can be determined and thus the particle qualities can be suggested. The advantage of this time-shift technique as opposed to the phase-Doppler technique is that it never overestimates even non-spherical particles and can, with the help of extensions, determine the size of suspension drops.